There are many reasons why

building inspections are conducted.

Governmental agencies use building inspections to check on compliance with building

plans and with local codes and ordinances. Building inspections are a routine part

of buying and selling homes, helping prospective sellers identify problems they

are legally responsible for and helping buyers know what they are getting into.

Property manager is also use inspections for preventative maintenance. Building

inspectors are called upon in the process of construction itself, to help the builders

with structural design issues, storm water handling issues, and electrical concerns.

As buildings age and settle, or weather storms, or undergo renovation or construction

of additions, building inspectors are often called in to address safety concerns.

Inspectors usually check the structure of the buildings as a whole, the foundation,

the roof, the electrical systems, the plumbing systems, the interiors of walls,

the attic, insulation, air conditioning, appliances, and pools.

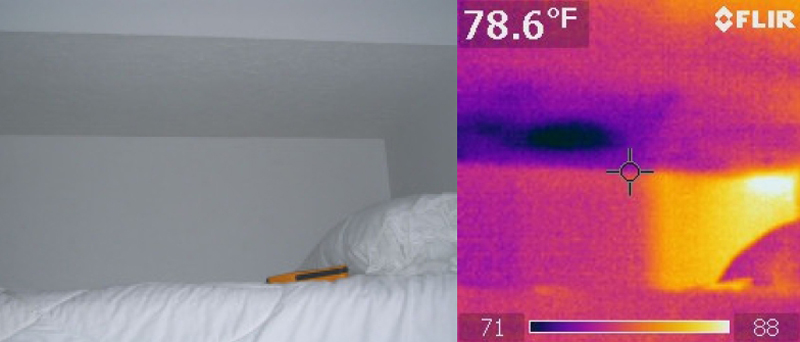

Leak Noted in the ceiling

|

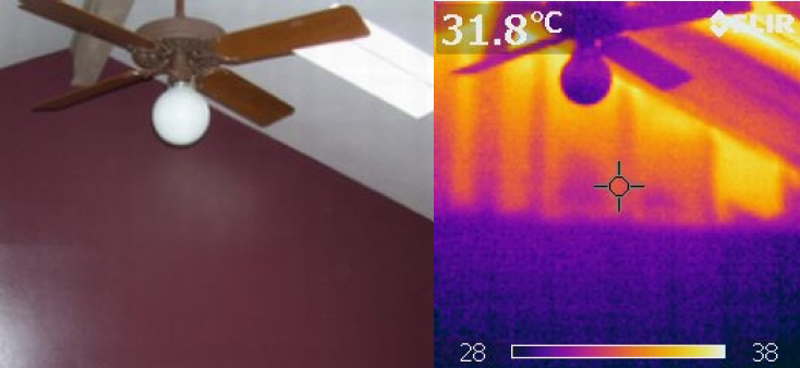

Leak on ducting

|

They also look for termites and other insect infestations, as well as mold and fungus

growth. Many of the tests done on these various systems are invasive and destructive.

They involve drilling holes in walls, removing whole sections of walls for inspection

ports, and similarly time-consuming and harmful techniques. Tests of appliances

and electrical systems often involve extensive work and analysis with various meters

in order to catch any potential problems, such as overheating or short circuiting.

It can be almost impossible for traditional building inspection techniques to catch

water damage inside walls and under the surfaces of roofs. Even to the experienced

eye, a roof or wall might look dry on the outside but in fact be ready to collapse

from rot on the inside.

The finding of water damage underneath a dry exterior surface is a matter of trial

and error, and is very invasive, involving a lot of drilling and cutting. When water

damage is found, whole roofs or walls often have to be replaced in order to fix

the problem, because there is often no easy way to determine exactly where the leak

started. While X-ray systems are sometimes used to see inside of walls and roofs

non-destructively, X-rays can only “see” certain types of materials, and not others.

They are very expensive and require a lot of training to properly use and, of course,

there are serious safety issues concerning their use. Infrared cameras provide a

way of seeing the insides of things. Because infrared cameras detect heat, using

them to scan for temperature differences on the outside allows building inspectors

to get a very good idea of what is going on in the inside.

Objects with different sizes, densities, and weights all absorbed and emit heat

differently. Therefore to an infrared camera, a wall that is insulated looks different

than a wall that is grouted, and both of them look different than a wall that is

just empty. Because an inspector with an infrared camera can see all the inside

areas of any structure, he or she can instantly determined if components are damaged,

missing, or out of place. Using infrared technology, there is no need for the destructive

testing methods of randomly drilling holes and installing inspection ports. Infrared

cameras provide a simple means of solving the problems of traditional inspection

methods. Infrared technology allows building inspectors to see problems they otherwise

would have missed such as water penetration of walls and roof, leaks in the plumbing,

electrical problems, and defects in the insulation.

The use of infrared cameras is not only able to detect hard to spot problems it

also allows building inspector is to see problems before they become serious issues.

Infrared inspection also helps inspectors to diagnose not just the extent to but

also the source of many of these problems. This can result in a large reduction

in costs. Early detection of moisture inside a wall, for instance, allows for an

early, simple, cheap fix which would not be possible much later, after extended

exposure to moisture creates a pervasive problem with mold. It is far cheaper to

replace the small section of roof where a leak originated than it is to replace

the whole roof. Infrared cameras provide a quick and effective method of moisture

tracking that allows the source of any leak to be readily determined.

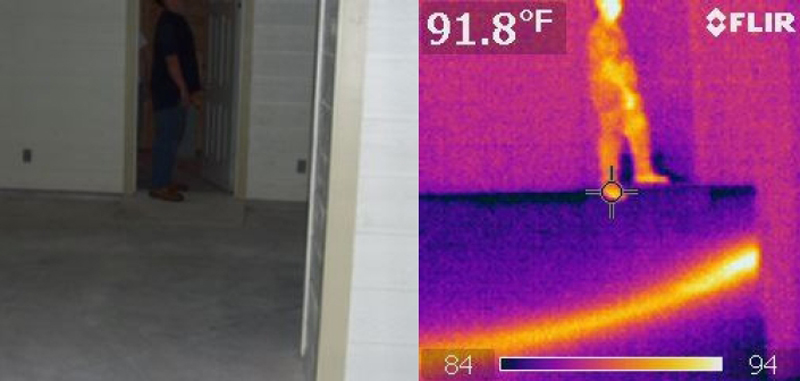

Water line in the slab floor |

Missing insulation |

Because infrared cameras “see” heat, inspection with them can readily identify loose

electrical connections, overloaded circuits, and shorts before electrical systems

fail or, worse, start fires. A small slow leak in the plumbing can be found just

by looking through an infrared camera, which is far cheaper than pulling out walls

and ceilings and looking over every inch of the plumbing by eye. Old-fashioned methods

of building inspection, such as visual surveillance, installation of inspection

ports, and even the use of x-rays are often ineffective when and always inefficient.

The use of infrared cameras makes building inspection not just far more effective

but also far more cost effective.